No one wants their life to be dominated by tedious and labour intensive activities, especially not laboratory staff. As a consequence automation is commonplace in laboratories. However this doesn’t always have to mean liquid handling robots and expensive bespoke solutions. Often a simple software program can save valuable time by doing several processing steps together, or a well designed dispenser can take the place of multiple manual pipette steps.

Up to 90% time saving

At CSols we’ve nearly 30 years experience building and implementing a range of low footprint, configurable and easy to install instrument integration applications (Links for LIMS, PrepLab & AqcTools). Often these applications reduce the administration effort during the instrument workflow process at our customer laboratories by up to 90% compared with doing it all manually. In turn this not only improves turnaround times but results quality by eliminating transcription errors.

Just the start!

However selecting Links for LIMS, PrepLab or AqcTools for your laboratory is just the start! CSols can offer you further automation options using Links for LIMS and AqcTools as the foundation level of your instrument integration strategy. By adding further software integration, instrument control and making use of partner products (such as the Phytronix LDTD® Laser Diode Thermal Desorption system), we can make significant improvements to your instrument based analysis workflows.

Your Automation Journey?

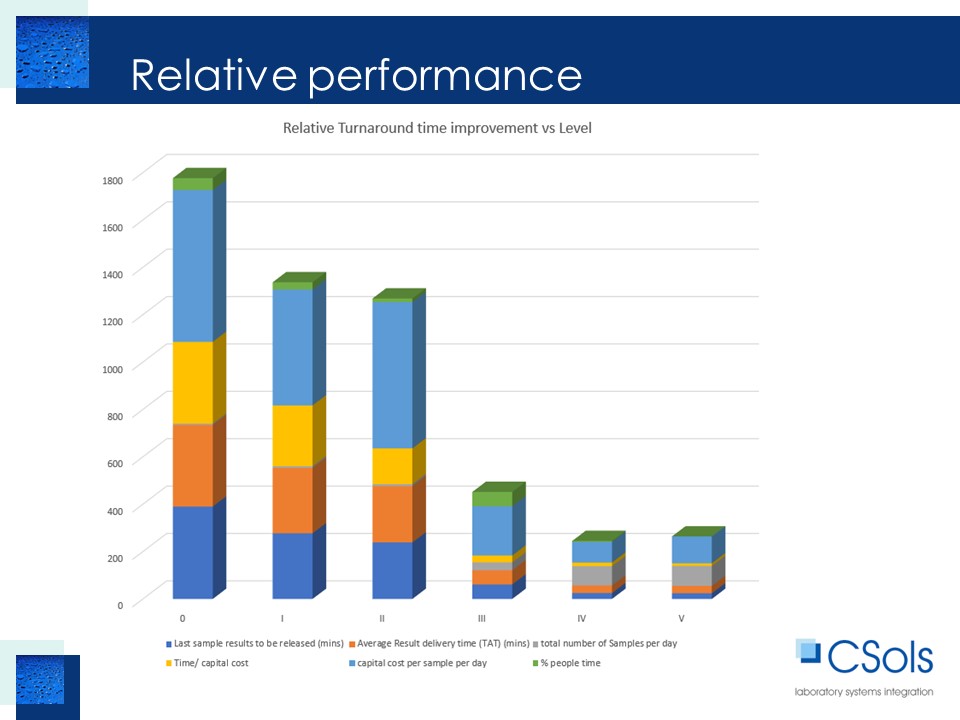

Using an LC-MS/MS based workflow as an example of a popular technique used in many industries, including the food, environmental, clinical and forensic sectors, we offer a number of automation levels, beyond manual transcription, where integration with Links for LIMS and/or AqcTools are at Level I. We hope that this example and article will give you an indication of the increased productivity we can offer you. The specifics will of course be different for your own laboratory, however if you’d like to learn more or discuss your own automation goals, please contact us via our email address : sales@csols.com or via our contact form.

Levels of automation

Here is an outline description of the levels for an LC-MS/MS based workflow. These will generally be the same for other instrumentation systems. Click on at each level for more details.

Level 0 – Manual transcription

Both instrument setup and results handling done manually with all transcription potentially double checked by a second analyst. AQC results and any other post run calculation, recoveries etc. would also done manually or via third party software like Excel. Jump to slide Level 0 for more information

CSols Links for LIMS and/or AqcTools software added to remove all routine administration work, including calculations and flagging. Jump to slide I for more information

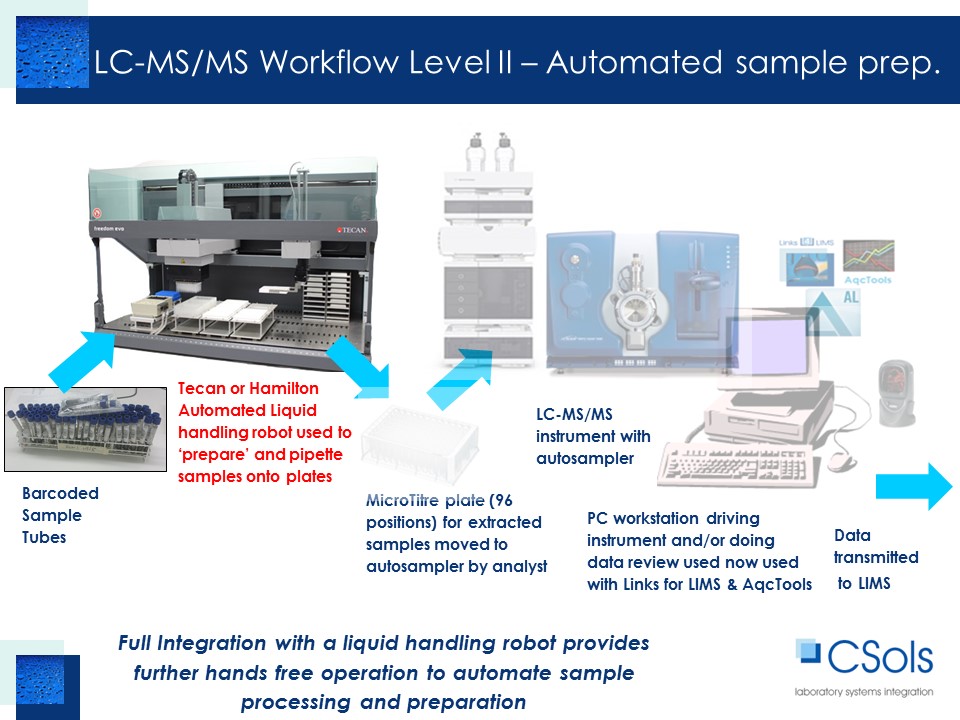

Introduction of an automated liquid handling system that automates and/or accelerates sample preparation required before analysis. May also be configured to read sample labels leading to the storage of instrument sequences for processed racks or microtitre plates. Jump to slide II for more information.

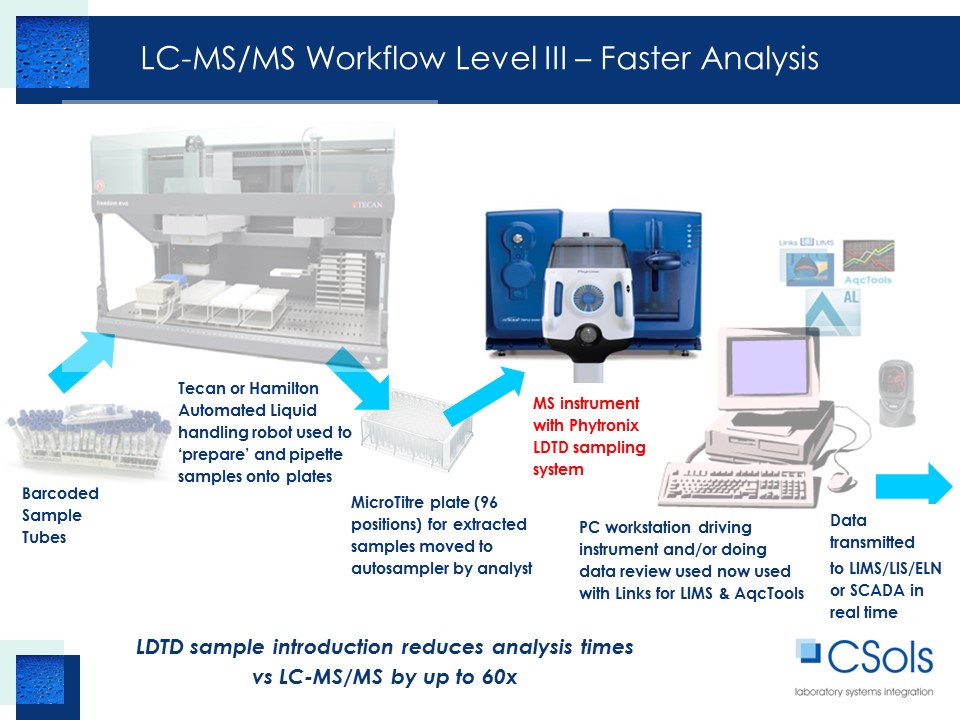

Level III – Faster analysis with novel sample introduction techniques (Phytronix LDTD)

Improve analysis times significantly by selecting an alternative sample introduction system. N.B. The Phytronix solution described here applies only to LC-MS/MS based analysis techniques, but each analysis technique has alternative approaches. Jump to slide III for more information.

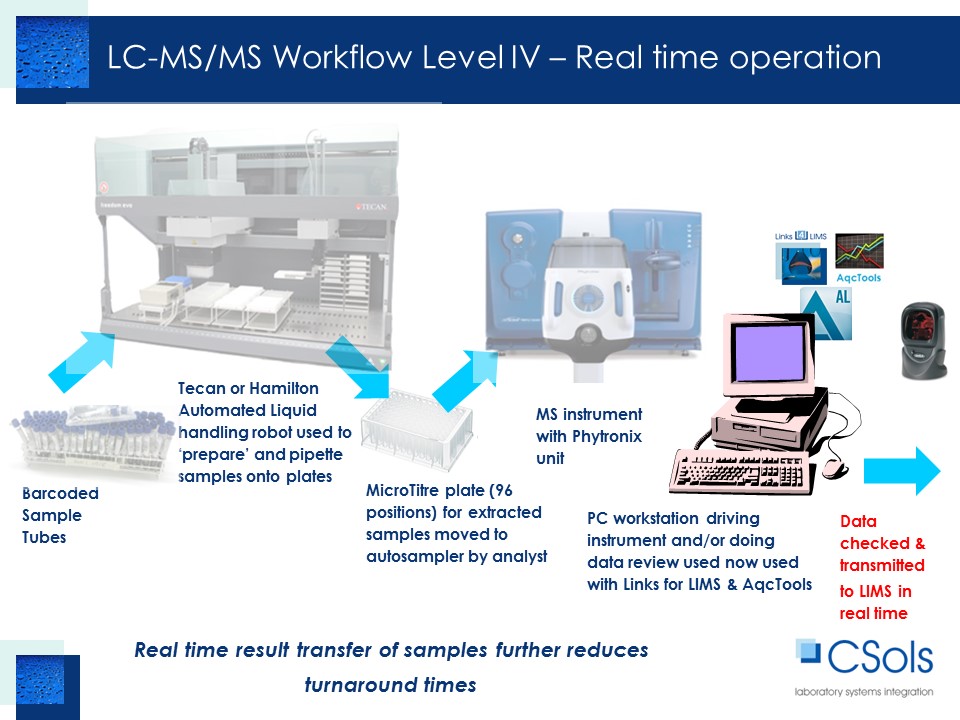

Level IV – Real time results and AQC processing (random access usage)

Why wait for the instrument to finish a batch. Send the results continuously? Jump to slide IV for more information.

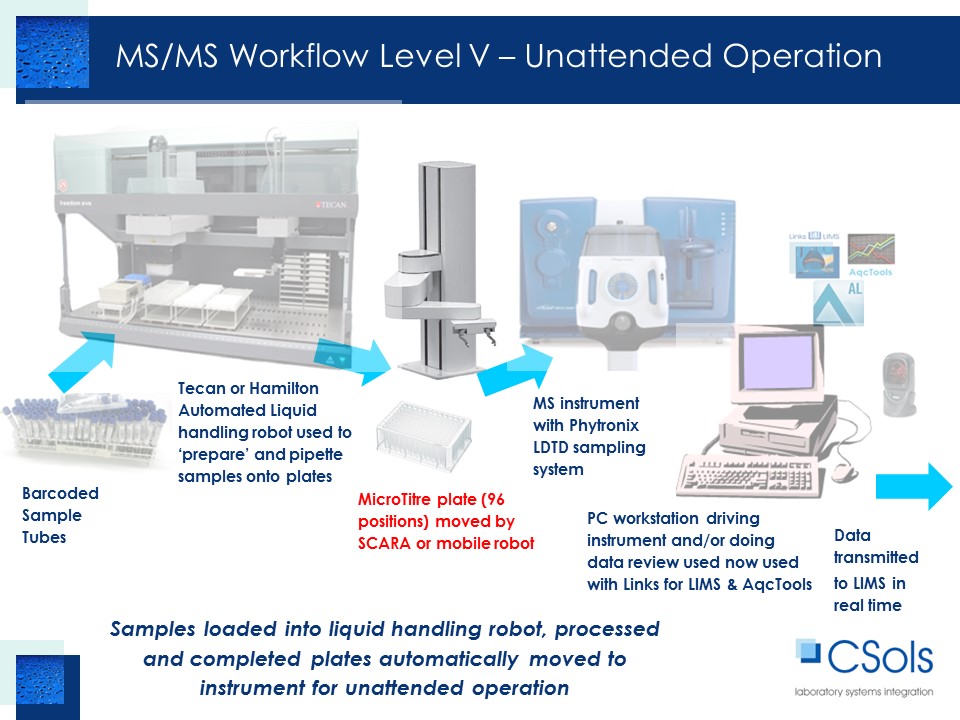

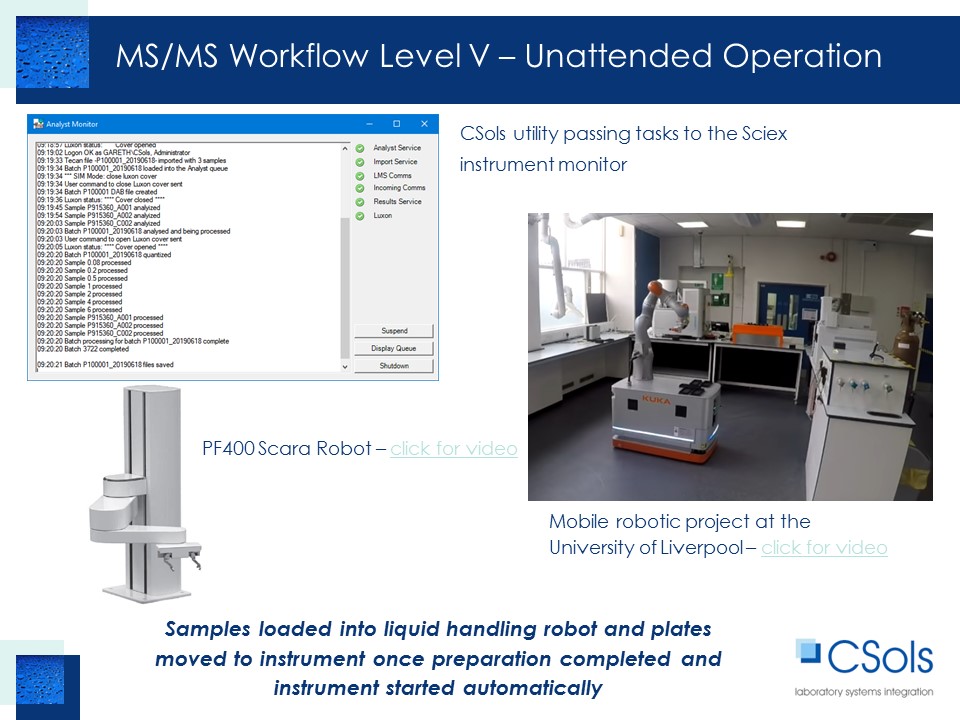

Level V – Unattended operation with stand alone or mobile robots

Cut out the manual transfer between liquid handling system and the instrument by using a fixed or mobile robot and run the instrument unattended? Jump to slide V for more information.

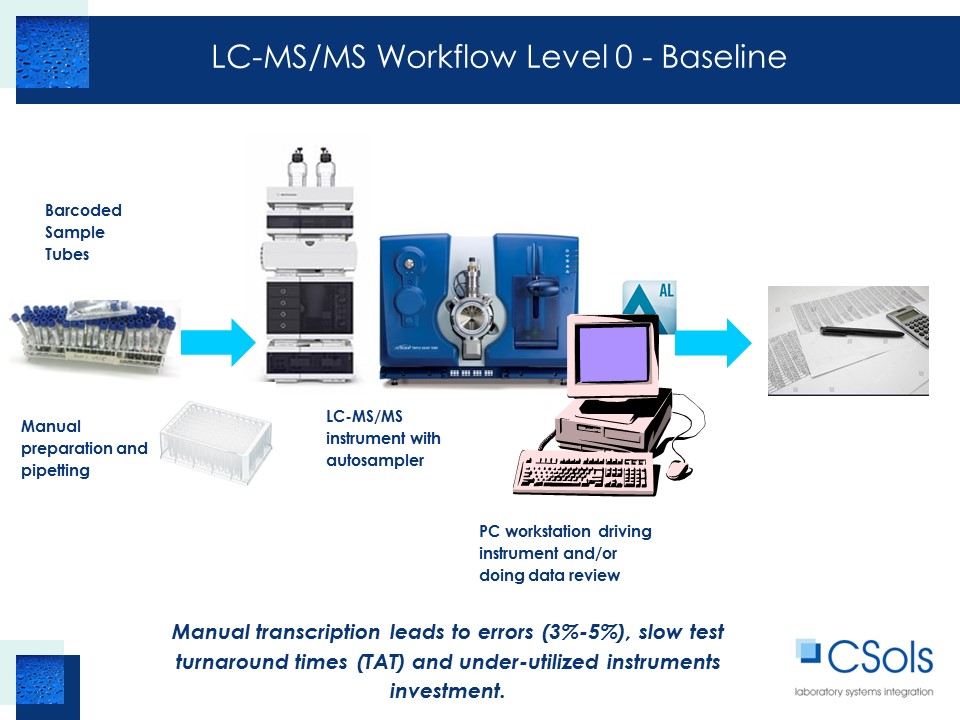

Level 0 – Manual transcription

A typical workflow with manual creation of instrument sequence (queue) would include the data entry of sample identifiers (duplicates if used), as well as assignment and naming of all control samples and a unique batch (worksheet) name. Once analysis is completed results must be printed or exported, calibration and other calculations/checks carried out, and reportable results (e.g. concentrations) manually transcribed to external IT systems such as LIMS/LIS, middleware, ELN, SCADA etc.).

Discussion : Time consuming, requires key personnel, error (detected and undetected) prone and inconsistent. Jump to Level I

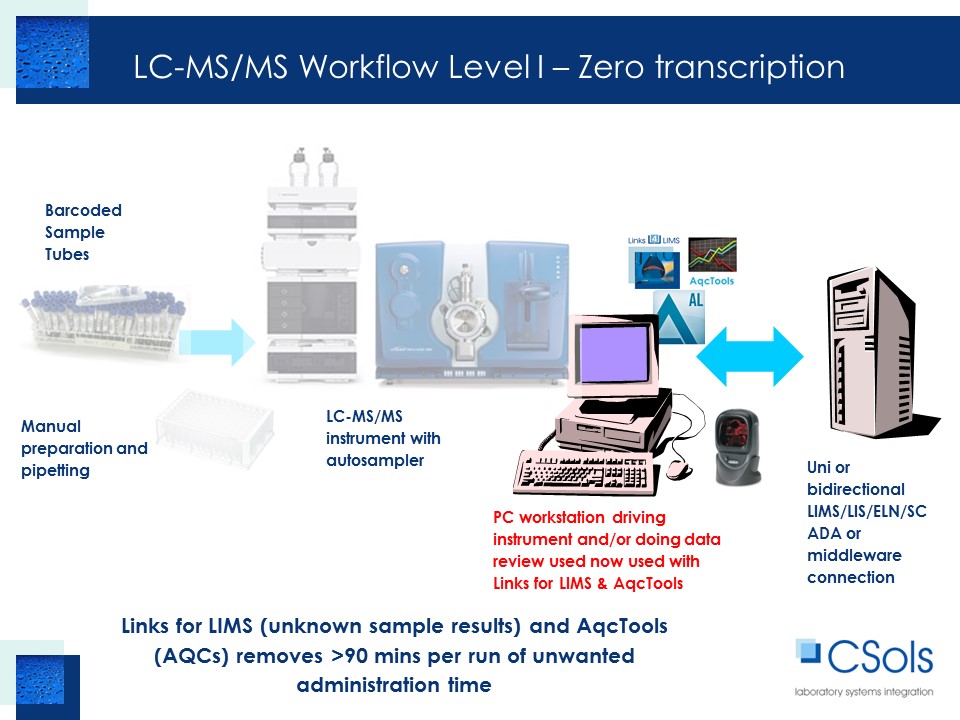

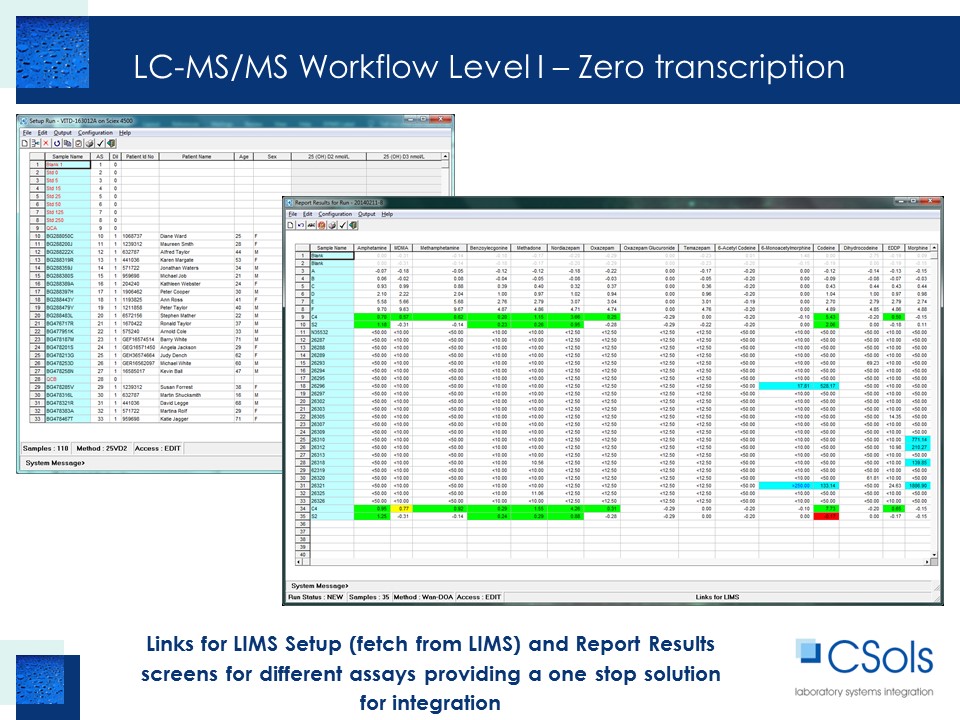

Level I – Integration of stand alone PC based instruments (e.g. LC-MS/MS) with Links for LIMS and/or AqcTools

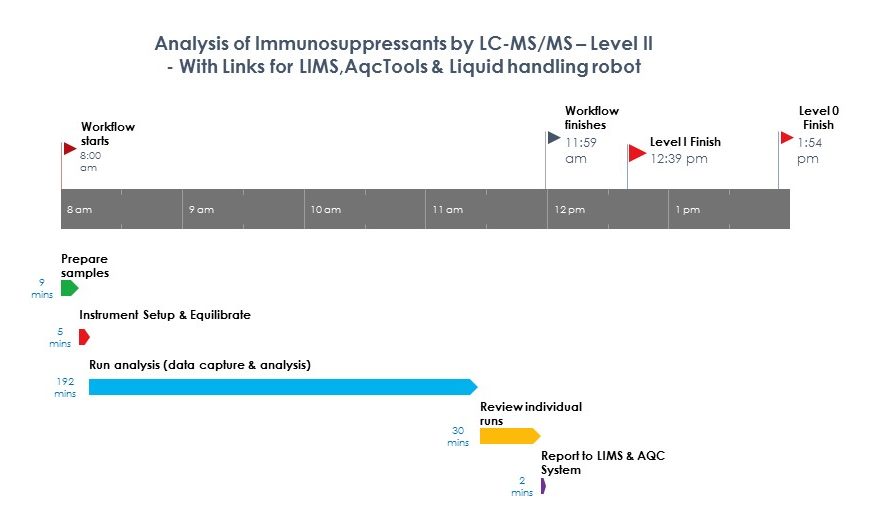

Links for LIMS and/or AqcTools software are installed onto the instrument PC workstation to handle i) all external communications with IT systems, ii) electronic instrument setup iii) results extraction, iv) results review and post run calculations, flagging, QC checks and v) all reportable results transmission and AQC results storage.

Discussion : >90 minutes analyst time saved per run, 3% to 5% errors eliminated, follows laboratory SOP so can be used by all laboratory staff, reduced analysis/test turnaround time (TAT). However Analysis and sample preparation times are unaffected.

Jump to Level II

Level II – Tight links with automated liquid handing systems (e.g. from vendors like Tecan, Agilent, Hamilton, Beckman, PerkinElmer etc.)

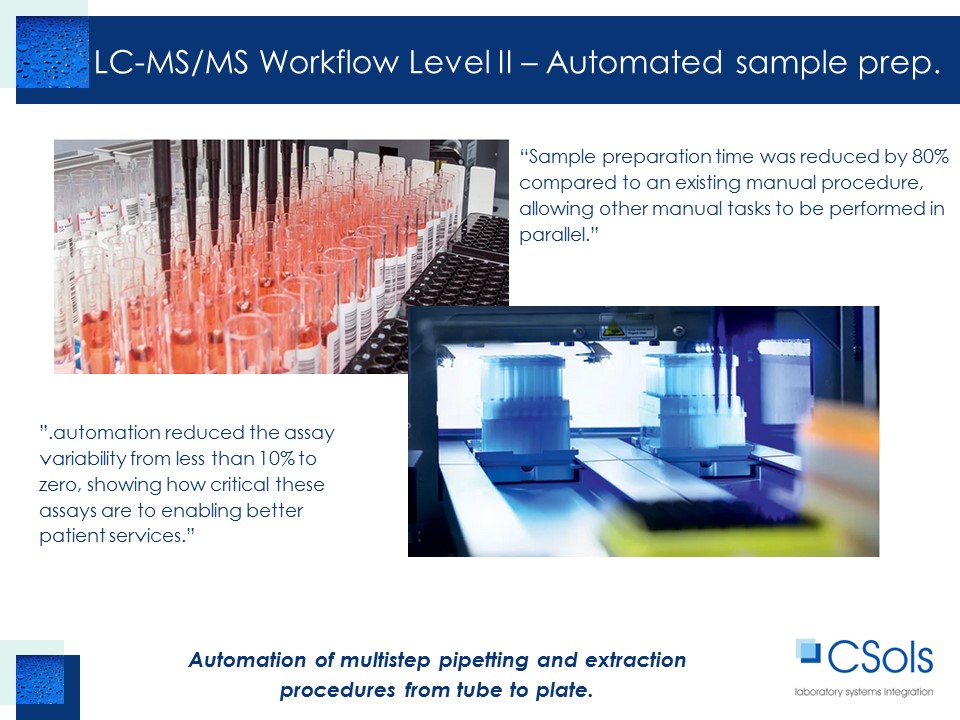

The introduction of an automated liquid handling system can save in the region of 80% of the effort used for equivalent manual sample preparation. So not only will analysts be free to do other tasks during the processing but there will be improvements in processing time and a reduction in pipetting and sample transfer, which will reduce repetitive strain injury (RSI). From an electronic perspective the software used by the liquid handling system usually exposes all sample identity information that it captures, as well an ‘audit’ log of sample processing history. This can be used by Links for LIMS to build an instrument batch sequence, further increasing integration.

Discussion : Easy way to create a batch sequence yet still having the option of inserting control samples and validating LIMS for the assigned test methods and other demographics.

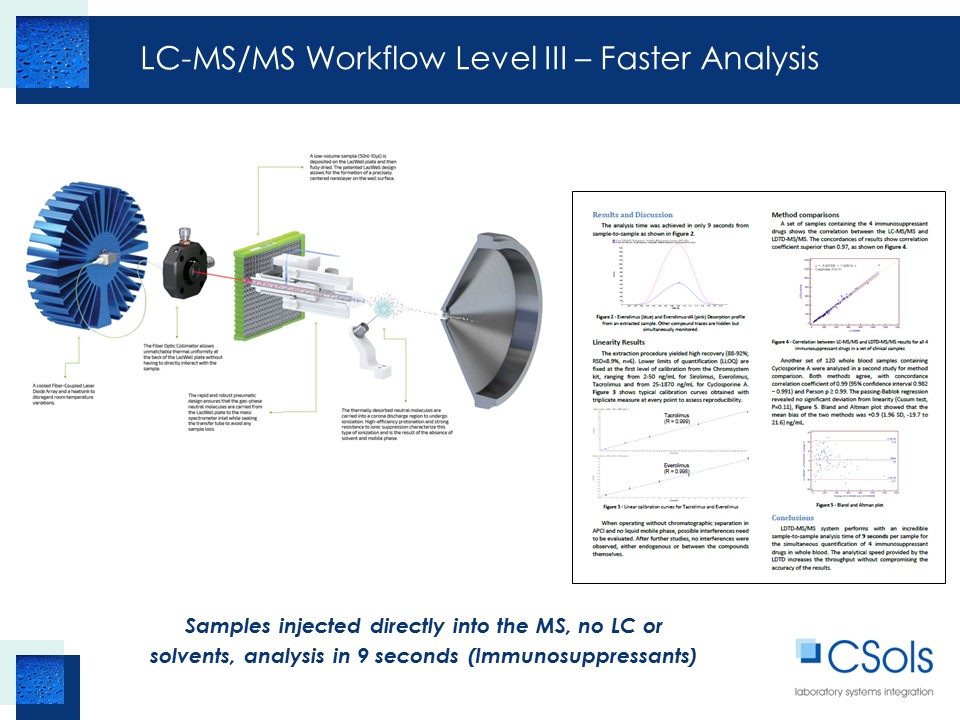

Level III – Faster analysis with novel sample introduction techniques (Phytronix LDTD)

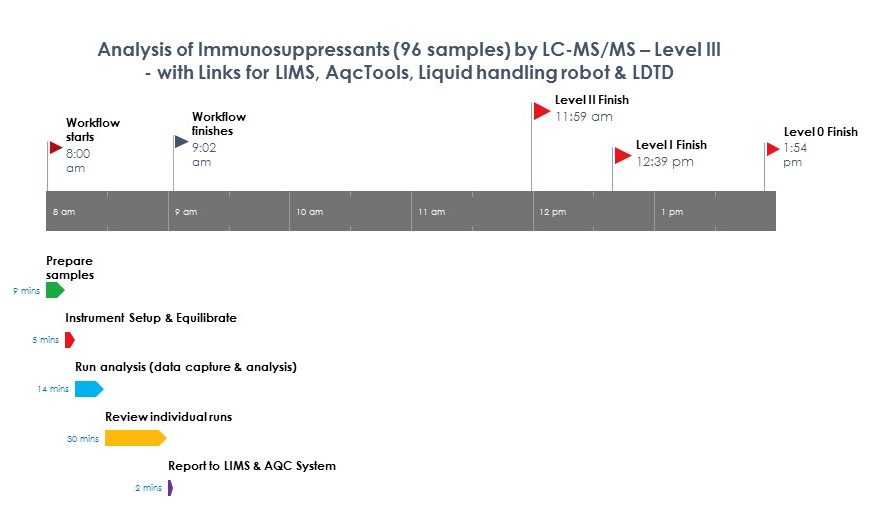

Even with improvements achieved via improved data administration (Level I) and sample preparation (Level II), for batch style techniques, analysis time still dominates the workflow. However employing the Phytronix Luxon Ion source in place of conventional LC based separations can reduce analysis times of Mass Spectrometry methods by up to 60x! Jump to our Phytronix page for more information.

Discussion : Creates a new dynamic for the assay, with a batch of analysis completed in an hour which would have taken all morning without automation.

Example timeline above using LC separation and below using the Luxon.

Level IV – ‘Real time’ results and AQC processing (random access usage)

Typically batch based analysis techniques are carried out with large number of samples, the size of which are often defined by the capacity of the autosampler being used. While the instrument software may provide a display of the data as it’s being captured and quantified, a review of the final results doesn’t take place until analysis is completed. Often analysis may take several hours. However if results could be released in ‘real time’, what sort of impact would this have on your laboratory? Used with or without the capabilities described in Level III above, CSols ‘Real time’ drivers can continuously monitor results emerging from analysis and quantification and transfer them if they are ‘ready for reporting’.

Discussion : Still need batch preparation, but with smaller batch sized could offer significant improvements in turnaround times. Perhaps suited to urgent or production samples.

Level V – Unattended operation with stand alone or mobile robots

The combined effect of Levels I to IV is very fast analysis, distributing quality results continuously throughout the instrument run. The final part of the workflow still being completed manually is the movement of tubes or plates from the liquid handling system to the instrument. This can now be done using a collaborative stand alone robot (e.g. a SCARA – Selective Compliance Articulated Robot Arm) or a mobile robot (e.g. an autonomous mobile robot) and running the whole workflow unattended.

Discussion : Sounds a little advanced? Well not everyone will be able to take advantage of all these Levels (not enough samples, unsuitable methods, finances) and so our automation journey may take you only to Level I. However even modest investments can save time, which in turn can change the way in which the laboratory and business it supports perceive routine operation, and lead to a justification to move to the next Level!

The specifics will of course be different for your own laboratory, however if you’d like to learn more or discuss your own automation goals, please contact us via our email address : sales@csols.com or via our contact form. Thanks for reading this article.